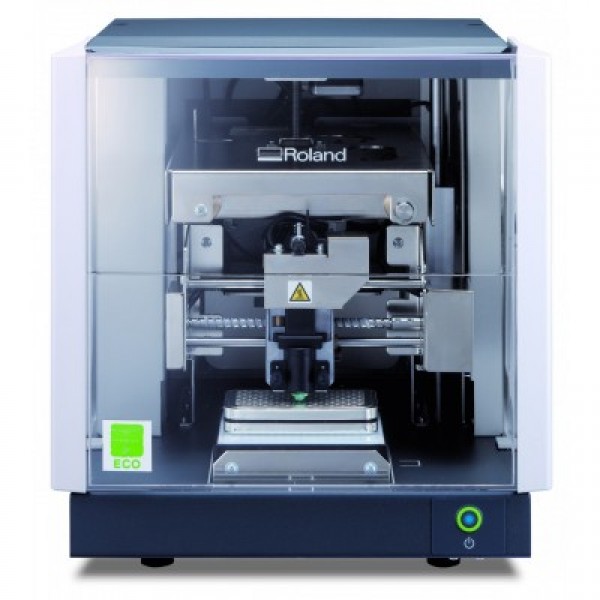

Roland MPX-90M

MPX-90M Direct Part Marking Device

- Designed for direct marking of GS1 DataMatrix barcodes for UDI compliance as directed by the U.S. Food & Drug Administration (FDA)

- Diamond-tipped stylus permanently marks hard materials up to 200 HV, including surgical steel, titanium and aluminum, as well as matte plastics and acrylics

- Bundled MetazaStudio software allows for quick setup of DataMatrix barcodes and QR codes, as well as text, symbols, photos and graphics

- Medically safe marking will not corrode or degrade materials over time

With the MPX-90M UDI barcodes impact printer, marking surgical instruments and tools with unique device identification (UDI) is more precise and affordable than ever. The MPX-90M quickly and accurately imprints large amounts of data in barcode format as small as 1mm2 on materials ranging from surgical steel and titanium to aluminum and acrylic. It does this in the most clean and user-friendly way possible, without debris, odor or fuss.

MPX-90M Highlights

- Mark GS1 DataMatrix barcodes for UDI compliance as directed by the U.S. Food & Drug Administration (FDA)

- Diamond-tipped stylus marks hard materials up to 200 HV

- Clean, precise workflow with no debris or odors

- Automatic surface detection for error-free imprinting

- Bundled METAZAStudio software for easy setup and operation

- Built-in laser pointer and adjustable XY vise

- Automated head height function ensures proper image placement

- Two nose cones facilitate marking on flat and curved surfaces

- Adjustable XY axis clamping table for holding flat and odd shaped tooling

- Variable data printing allows automatic imprinting of unique serial numbers, production lot dates and other sequential data

- Mark GS1 DataMatrix barcodes for UDI compliance as directed by the U.S. Food & Drug Administration (FDA)

- Diamond-tipped stylus marks hard materials up to 200 HV

- Clean, precise workflow with no debris or odors

- Automatic surface detection for error-free imprinting

- Bundled METAZAStudio software for easy setup and operation

- Built-in laser pointer and adjustable XY vise

- Automated head height function ensures proper image placement

- Two nose cones facilitate marking on flat and curved surfaces

- Adjustable XY axis clamping table for holding flat and odd shaped tooling

- Variable data printing allows automatic imprinting of unique serial numbers, production lot dates and other sequential data

Clean, High-Speed Marking on Hard Metal Surfaces

The MPX-90M uses a durable diamond-tipped stylus to directly imprint on titanium, stainless steel and other hard metals. Engineered for speed and precision, the MPX-90M can quickly imprint up to 26 digits of information inside an area as small as one square millimeter. Because it does not burn or remove material on impact, the MPX-90M generates no odors or debris. No daily maintenance or special power or ventilation is required.

The MPX-90M uses a durable diamond-tipped stylus to directly imprint on titanium, stainless steel and other hard metals. Engineered for speed and precision, the MPX-90M can quickly imprint up to 26 digits of information inside an area as small as one square millimeter. Because it does not burn or remove material on impact, the MPX-90M generates no odors or debris. No daily maintenance or special power or ventilation is required.

METAZAStudio Software Included

The MPX-90M comes with METAZAStudio software, which instantly converts your numerical data to 2D DataMatrix barcodes that meet GS1 and other formats. In addition to DataMatrix barcodes, the MPX-90M imprints numbers, text, symbols, logos, photos, QR codes and other graphics with precision.

| MODEL | MPX-90M |

|---|---|

| Printable Material | Gold, silver, copper, platinum, brass, aluminum, iron, stainless steel, acrylic, etc. Vickers hardness (HV) of the printable surface must be 200 or less. |

| Loadable material size with cover closed | 3.94(W) x 7.87(L) x .80(Thick) in. - 100(W) x 200(L) x 20(Thick) mm or 7.87(W) x 3.94(L) x .80(Thick) in. - 200(W) x 100(L) x 20(Thick) mm |

| Printable area | 3.15 x 3.15 in. (80 x 80 mm) |

| Resolution | 265 dpi (Text) 353 dpi (Photo) 529 dpi (High Resolution) 1058 dpi (Vector) |

| Print speeds | 1.29 in./sec (33 mm/sec) – Text/High Resolution Mode 1.97 in./sec (50 mm/sec) – Photo Mode 0.94 in./sec (24 mm/sec) – Vector Mode |

| Interface | USB Interface (Compliant with Universal Serial Bus Specification Revision 1.1) |

| Power Supply | Dedicated AC Adapter: AC 100V to 240V +/- 10%, 50-60Hz |

| Machine: DC 19V, 1.6A | |

| Power Consumption | Approximately 24W |

| Acoustic Noise Level | Under 70dB (A) |

| Operation Temperature | 50 to 86°F (10 to 30°C) |

| Operation Humidity | 35 to 80% (No condensation) |

| External Dimensions | 11.3(W) x 15.1(D) x 12.2(H) in. - 286(W) x 383(D) x 308(H) mm |

| Weight | 24 lbs (11 kg) |

| Included accessories | AC adapter, power cord, test print material, USB cable, MetazaStudioSoftware CD-ROM, vise and user’s manual |

| COMPUTER SPECIFICATIONS | |

| Operating system (OS) | Windows XP/Vista/7 (32 and 64 bit editions) |

| CPU | Pentium 4, 3.0GHz or more recommended |

| Memory | 512MB or more recommended |

| Required hard disk space | 20 MB for software application (more recommended for storing templates and libraries) |

| Compatible file formats | MetazaStudio: JPG, BMP, AI, EPS (Adobe Illustrator 8.0 export, CorelDRAW) |

MonoFab ARM-10 Desktop 3D Printer

- Digital Light Processing (DLP) layered projection system produces semi-transparent models for concept and form testing

- Fully enclosed cabinet for safety

- Easy to use - controlled with a single button

- Build area: 5.11" W x 2.75" D x 2.75" H

Turning your ideas into real world objects is as simple as hitting “print” with the monoFab ARM-10 3D printer. With the advanced, precise and user-friendly ARM-10 rapid prototyping 3D printer, complex parts which previously required multi-axis milling, such as hollow or requiring undercuts, can be built quickly and easily.

The Magic of Stereolithography Technology

To see an object being created using stereolithography rapid prototyping 3D printing is a true technical marvel. The layered projection occurs in the following process:- The image platform on the ARM-10 is lowered into the material tray containing imageCure photopolymer resin so that the surface of the platform is a single layer beneath the surface of the resin.

- An LED-based DLP projector beams UV light that cures a cross section of the model, solidifying the resin wherever the resin is exposed.

- Once a layer is complete, the platform ascends to a second layer of thickness, resin flows over the first layer, and the next layer is built until the process is complete. This allows multiple objects to be produced at the same time.

- Once the model is complete, the platform rises out of the material tray and the excess resin runs off the model back into the material tray.

- The machine operator can now remove the model from the platform, wash off excess resin, and place in daylight or other UV curing devices for a final curing.

- The model can be finished by removing the temporary supports and sanding or filling the remaining supports if necessary.

- The image platform on the ARM-10 is lowered into the material tray containing imageCure photopolymer resin so that the surface of the platform is a single layer beneath the surface of the resin.

- An LED-based DLP projector beams UV light that cures a cross section of the model, solidifying the resin wherever the resin is exposed.

- Once a layer is complete, the platform ascends to a second layer of thickness, resin flows over the first layer, and the next layer is built until the process is complete. This allows multiple objects to be produced at the same time.

- Once the model is complete, the platform rises out of the material tray and the excess resin runs off the model back into the material tray.

- The machine operator can now remove the model from the platform, wash off excess resin, and place in daylight or other UV curing devices for a final curing.

- The model can be finished by removing the temporary supports and sanding or filling the remaining supports if necessary.

| MODEL | ARM-10 | |

|---|---|---|

| Build technology | DLP layer projection system | |

| Build size | 5.1 (W) x 2.7 (D) x 2.7 (H) inches (130 (W) x 70 (D) x 70 (H) mm ) (Job volume of resin is up to 0.7 lbs (300 g)) | |

| Build speed | .393 inch (Layer pitch = 0.0059 inch) (10 mm/h (Layer pitch = 0.15 mm)) | |

| Light source | UV-LED (ultraviolet light emitting diode) | |

| XY resolution | .0079 inch (0.2 mm) | |

| Z axis resolution | .0004 inch (0.01 mm) | |

| Power | Machine:DC 24 V, 0.6 A Dedicated AC adapter: AC 100 V to 240 V±10%, 50/60 Hz | |

| Power consumption | 15 W | |

| Acoustic noise level | During operation: 55 dB (A) or less During standby: 49 dB (A) or less | |

| Dimensions / Weight | 17.0 (W) x 14.4 (D) x 17.8 (H) inches / 37.5 lbs 430 (W) x 365 (D) x 450 (H) mm / 17 kg | |

| Interface | USB | |

| Installation environment | During operation | Temperature of 68 to 86°F, 20 to 30°C, 35 to 80% relative humidity (no condensation) |

| Not operating | Temperature of 41 to 95°F, 5 to 40°C, 20 to 80% relative humidity (no condensation) | |

| Accessories | AC adapter, Power code, USB cable, Liquid material tray, Printing and washing tools (Metalic spatula, Plastic spatula, Tweezers, Washing container x 2, Hexagonal wrench, Spanner, Rubber gloves, Work tray, etc.), Start-up page information card, Read this first.

| |

| Optionally Available Items | ||

|---|---|---|

| Item | Part Number | Description |

| Resin | PRH35-ST | 350 g bottle |

| Liquid material tray | LMV-10 | For replacement

|

| System Requirements (ARM-10) | |

|---|---|

| Operating system (OS) | Windows 7/8/8.1 (32-bit/64-bit edition)* |

| CPU | Intel® Core 2 Duo or more (Core i5 or more recommended) |

| Memory (RAM) | 1GB (2GB or more recommended) |

| Video card and monitor | A resolution of 1,280x1,024 or more recommended |

| Free hard-disk space required as a working space | 100 megabytes or more recommended |

| Other requirements | Internet connection and web browser, Internet Explorer version 10 or more recommended |